STANDARD DEWATERING BAGS

Each Standard Sediment Bag is constructed from a robust geotextile filter fabric to catch and contain sediment as muddy water is pumped from your site. These filtering bags are made from a non-woven geotextile fabric that is needle-punched to allow water to flow back out while retaining fine soils and particles. Its high filtering qualities make it ideal for pumping trenches, construction sites, dredging areas, ponds, lakes and for dewatering inmunicipalities or plants.

Standard Sediment Dewatering Bags are the most common option for removing unwanted materials from discharge or stormwater runoff. Bags are generally smaller in size, making them ideal for dumpsters, drop boxes, or other small dewatering areas.

Their components meet or exceed minimum DOT Erosion and State NPDES Sediment Control requirements as outlined in 40 CFR 122.26. GEI’s Dewatering Tubes help keep runoff clean and keep your site in compliance with local and federal stormwater regulations.

- Needle-punched, non-woven geotextile fabric

- Filters soils and particles as small as 4x the width of a human hair

- Quick and intuitive installation

- Works with up to 8 in. diameter discharge hoses

- Helps comply with NPDES Phase II regulations

- Filtration

- Dewatering

- Dredging

- Sediment Removal

- Bank Reinforcement

- Contaminated Sediment Removal

HD DEWATERING BAGS

Their components meet or exceed minimum DOT Erosion and State NPDES Sediment Control requirements as outlined in 40 CFR 122.26. GEI’s Dewatering Tubes help keep runoff clean and keep your site in compliance with local and federal stormwater regulations.

- Made with heavy-duty needle-punched, non-woven geotextile fabric

- Filters soils and particles as small as 3x the width of a human hair

- Quick and intuitive installation

- Fits up to 8 in. diameter discharge hoses

- Helps comply with NPDES Phase II regulations

- Filtration

- Dewatering

- Dredging

- Sediment Removal

- Bank Reinforcement

- Contaminated Sediment Removal

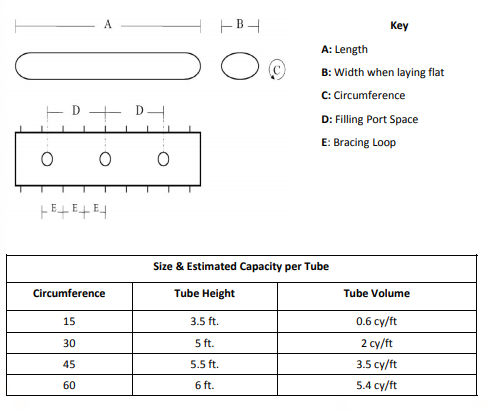

DEWATERING TUBES

Dewatering Tubes or Geotubes, are a reliable and cost-effective solution to manage water on your construction site, industrial project, or environmental remediation site for volumes that are measured in cubic feet of sediment. GEI Works’ high-quality dewatering tubes are designed to handle large volumes of water. They are the ultimate tool for effective sediment and water separation, ensuring clean and clear results.

Dewatering Tubes are used extensively in construction and protection of water infrastructure systems. Applications include on-land and off-shore marine applications. These close-ended tubes contain filling ports evenly spaced at intervals along the length to allow for even hydraulic filling of a slurry of sand and water. Their long exteriors and high permittivity allow them to effectively remove waste solids and other pollution from water while leaving sand and solids inside the tube. After drying, the sediment creates a solid horizontal structure of compacted sand and / or dried mud.

Dewatering Tubes are perfect for large dewatering filtration or sludge removal projects. Dewatering tubes have significantly larger dimensions and superior strength woven geotextile fabric or composite materials, as compared to the smaller footprint and non-woven material of dewatering bags. Once on site, Geotextile Dewatering Tubes are hydraulically filled with saturated sediment, sand or bio-organic solids and waste materials. When fully dewatered,

the sediment is reduced in both weight and volume, allowing for more cost-effective material handling.

Their components meet or exceed minimum DOT Erosion and State NPDES Sediment Control requirements as outlined in 40 CFR 122.26. GEI’s Dewatering Tubes help keep runoff clean and keep your site in compliance with local and federal stormwater regulations.

Click to learn more about our dewatering tubes.

- Increased storage capacity for long-term projects

- Made with weaving polypropylene fabric with superior tensile strength value

- Can effectively run 24/7

- Stackable and compatible with multiple filling ports

- UV Stabilized

- Lengths up to 250 ft

- Erosion Control

- Coal Ash Ponds

- Industrial Sludge

- Mine Tailings

- Wastewater Treatment Facilities

- Contamination Cleanup

- Shoreline or Beach Restoration

- Coastal and Wetland Operations

- Landscaping

- Excavating and Grading

- Concrete

- Utilities

- Asphalt & Paving

- Landfill

DEWATERING SOCKS

Their components meet or exceed minimum DOT Erosion and State NPDES Sediment Control requirements as outlined in 40 CFR 122.26. These pipe socks help keep runoff clean and keep your site in compliance with local and federal stormwater regulations.

- Overlocked Chain Stitching

- J-seams for superior strength

- Needle-punched, non-woven geotextile fabric

- Quick and intuitive installation direct to a discharge hose or pipe

- Easy to ship and store on site

- Filters soils and particles as small as 4x the width of a human hair

- Fits 4 – 16 in. diameter discharge hoses

- Can be implemented as a SWPPP solution or Stormwater BMP

- Helps Sites Comply with NPDES, 40 CFR 122.26 (1999)

- Filtration

- Dewatering

- Dredging

- Sediment Removal